Rustic Kitchen Tables are one

of the larger items we sell regularly at Redwood Burl Inc. By larger, I

mean up to 20 plus feet in length. Rustic can have many meanings. Here

is a link to Rustic Furniture on Wikipedia. When most people think rustic kitchen tables, they think Farmhouse Table. These were usually made using Salvaged materials, or whatever materials were available to you at the time.

Here,

in the "Heart of Redwood Country" Humboldt County, CA, people have been

taking a different approach to Salvaged materials for over a century.

We've been using Salvaged Redwood to make our version of the "Rustic

Kitchen Table". One big advantage to using Salvaged Redwood is we are

able to make rustic tables out of a single piece of wood. This is due to

the incredible size that Redwood Trees grow; having a diameter of close

to 30 feet at the base. In fact, a newer "Fatter" tree was just recently discovered.

Today,

Old Growth Redwood Trees are a protected resource. Barely a quarter of a

million acres of Old Growth remain. They are found either in State

Parks or Forest Reserves of some type such as the Headwaters Forest pictured below.

Photo courtesy of Save the redwoods league

ETHICAL SOURCING

Before any wood can enter our facility, it must be inspected. We have to know where the wood came from and how it was obtained. Whether it comes from private property or a large lumber company, we are looking for either Salvaged "Buckskin" Logs or harvested tree stumps from private land. Our "How we do it" Page will give you more information on this.The owner, Landon Buck, personally authenticates the origin of all wood before transporting it to our yard, where it is stored until milled into slabs. We are very resourceful, and from what I've seen, we can transport pretty much anything, either by truck with a Gooseneck trailer or a logging truck if need be.

On occasion, the wood sometimes needs a bit more processing before being moved to our facility. In this case we just have to make it smaller and more manageable, as you can see in the following video:

Rustic Kitchen Tables - Milling slabs from logs & stumps

We

usually store our wood in our large main yard until it is slated to be

processed into a more usable form, such as a slab. We have several mills

here at our facility, each one for cutting a different type of

material. In the spirit of keeping some secrets, this page is only going

to be focusing on our older technology.

In the following short video, you can see one of our mill operators cutting slabs out of a Salvaged Redwood Root Burl:

We

are very fortunate to have a big enough facility to store all of our

cut slabs indoors, year round. All of our wood is stored with "stickers"

between them allowing air to move between to slabs, dissipating

moisture into the air at a higher rate. In addition, five big truck

doors on our warehouse ensure plenty of air flow through our building.

Here are some pictures of our storage areas. If you are looking for

Rustic Kitchen Tables, our indoor facility is right up there with a trip

to heaven from what I've been told.

Rustic Kitchen Tables - Determining the size of your table

When

determining the size of your rustic kitchen table, there are a few

things to consider. The first is the size of your room and the space

available for your table. You then need to consider how many people

you're going to want to seat around that table. Lastly, you will need to

take into consideration any environmental considerations such as

chandeliers and the like, in case you need to ensure the table is

positioned in a certain way.

When

considering room size, you will want to leave 42" to 48" of space

around your table for walking and room for moving chairs back away from

the table. Also consider other items that will be in the room, such as

buffets or serving carts, etc. You can better visualize the tables

actual space by setting a sheet on the floor, folded to your table size.

Newspaper or cardboard templates will also work.

To

determine how many people will be able to sit down you want to start

with a slab with a width of about 36-40". We then usually estimate about

24" per/person. A 4' long slab seats two people on each side while a

10' table seats five per side. This allows one person on each end,

unless your table is in the 4'+ width range, then you might be able to

put two or more on each end.

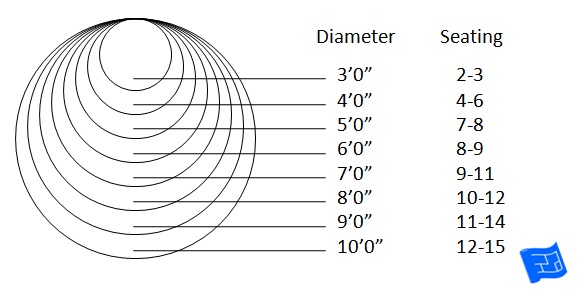

Round or square tables are also an option, below is a chart for sizing round tables:

Lastly,

you will need to determine the height of your table. For this, we need

to consider your seating arrangement. Normal table height is about 28"

to 30". However, if you have chairs with arms, you will need to measure

the arm height and table thickness to determine your final height. For a

counter height rustic kitchen table, you are looking at about 36" tall.

For a bar height kitchen table w/ bar stools, you would want closer to

40" tall to enable you to scoot under the table top a bit.

I myself have a bar height kitchen table/kitchen countertop with bar stools all the way around it. Because of the height I've been able to use a wide base that incorporates some sturdy shelving to store our cast iron pans. The base is also far enough from the edge of the slab top to accommodate wheel chairs as well.

Rustic Kitchen Tables - Types of Grain

Once

you have determined the size of your Rustic Table, you are ready to

move on to the next step and pick your slab. You will find our site is

broken up into sections accordingly. Your longer table are going to

require a Tree Slab. These are cuts from the longest part of the tree,

the trunk. This is where our big logs come from. For a square or round

table, you would want to take a look at our Burl Slabs.

These are from the stump area of the tree and are wider. Keep in mind,

these burl slabs may need to be cut and shaped to your final dimensions.

Now

it is time to consider what type of Character you want for your table.

This is essentially the type of grain you're going to want. The more

economical slabs have less going on in them grain wise , or what we

refer to as straight grain.

Straight grain and Curly grain Pictures:

Rustic Dining Table w/Straight Grain. Photo Courtesy of www.littlebranchfarm.com

Curly Grain Rustic Kitchen Table Photo courtesy of www.littlebranchfarm.com

For

pieces with more character, or better grain, it helps to know what type

of grain you are looking for. Take a peek at this page on our site for

more information on Burl and its grain patterns. The better the grain, the higher the Premium will be on that wood.

The

reason for the Premium is that not all Redwood has spectacular grain.

Salvage Logs tend to have better grain than most logs in general. This

is because most Salvaged logs are usually Buckskins, or logs from a

previous harvest. These logs were left behind because they were not

lumber quality. At the time, these logs were not worth moving and were

left where they fell. These logs were not Lumber Quality because they

had spectacular grain that was not suitable to be milled.

Curl

is a perfect example of spectacular grain that looks incredible in a

Rustic Dining Table. Curl is a Compression Grain. It is caused when

trees grow on a hillside, straightening themselves out in the process.

This straightening causes a compression grain on the uphill side of the

tree, usually along the edge, but on rare occasions all the way across

as well. Because Curl is so rare, these high quality pieces demand a

premium price.

Another

factor that will effect price is width. Wider slabs get a premium price

for the same reason, they are far and few between. Since large Redwoods

are no longer harvested, the only way to get these wider Salvaged Logs,

is to buy them from the lumber companies. They know what they are

selling, and they too demand a premium as well.

Today,

good Burl is not as readily available as it once was, even here in the

Heart of Redwood Country. People have been hunting burls here for more

than 100 years. It was always a good way to make some income on the

side, especially in the off seasons. Most people accumulated small stock

piles of burl material, to come back for in the off season, which can

last several months here on the West Coast. The point being, that all

of the easy burls to get, have already been got.

With

the policies that we have in place today. We are no longer purchase

wood from just anyone trying to sell it for a good price with out

knowing its provenance. Today, we've taken a firm stand in favor of our

environment. If it came to the point where we were not able to get more

logs due to an end in supply, we have the inventory to be able to keep

our mills running 8 hrs. a day for another 5 years or more.

Rustic Kitchen Tables - Choosing your slab

Now,

having your final dimensions and an idea of what you are looking for in

terms of Character, it time to build a table. For your larger rustic kitchen tables, I would suggest you start on our Dining Tables Page for slabs over 36", and our Conference Tables

for slabs in the 44" - 60" range. Basically what you are looking for is

something the right size or larger than what you actually need, as we

can always re-size the slabs smaller. As I've mentioned previously,

prices on the same size piece of wood may vary based on the grain, so

find the combination you feel comfortable with, and give us a call.

If

you don't see just what you are looking for, take note of the slabs you

do like, even if they are sold or too small. When you call, let us know

what it is about those pieces that you like, and in our vast inventory

we can most likely find you the perfect piece. Only a small fraction of

our inventory can be put online and we make updates daily.

Rustic Kitchen Tables - Finishing

Once

you have decided on a slab, it's time to think about finish. The beauty

of buying your slabs from us is, that you can buy just the material and

finish it yourself, or buy a fully finished table ready to use. I

personally am the do it yourself kind of guy so I have to do it myself!

Last year I took a slab home for the kitchen in my own home, but it was

not quite ready for a hard finish. I stained it, installed it, and I'm

going to finish it right this summer.

If

you decide to "do it yourself", you can have your slab shipped directly

to your home or a commercial address of your choice. We can help you

pick a finish based on your application, and give you some pointers

along the way. You can also find information right here in our Blog.

The

other option is to have the table fully finished for you. You can order

it already finished from us or have it done locally. We are able to

finish right here in house and we do a fabulous job. We can also have it

finished by the best finisher we know, who has been working with our

wood for years. Kelly at www.littlebranchfarm.com.

We can arrange to have it shipped there on his next regular shipment at

no charge, and you will just pay for the shipping from Nashville, TN to

your location.

Kelly has

been finishing tables for us for years now. He uses his own proprietary

finish that dries good and hard and lasts for years. The main reason we

do not finish everything in house is climate. We are within a mile from

the West Coast, and our average daily temperature is only 60°, not warm

enough for a finish to dry most of the year. While Nashville has more

extreme weather, it is much warmer overall. This makes it more suitable

for getting a nice finish to dry.

Rustic Kitchen Tables - Shipping info

We

can ship our slabs anywhere in the country and also internationally. We

will get you a big discount off of normal Fed Ex and Con-Way shipping

rates. Shipments to a commercial address are going to save you a bit of

money but we are also able to offer residential delivery with lift-gate

service right to your door. Finished tables do ship at a higher rate than raw wood, but we still get you that big discount!

service right to your door. Finished tables do ship at a higher rate than raw wood, but we still get you that big discount!